Food industry portfolio

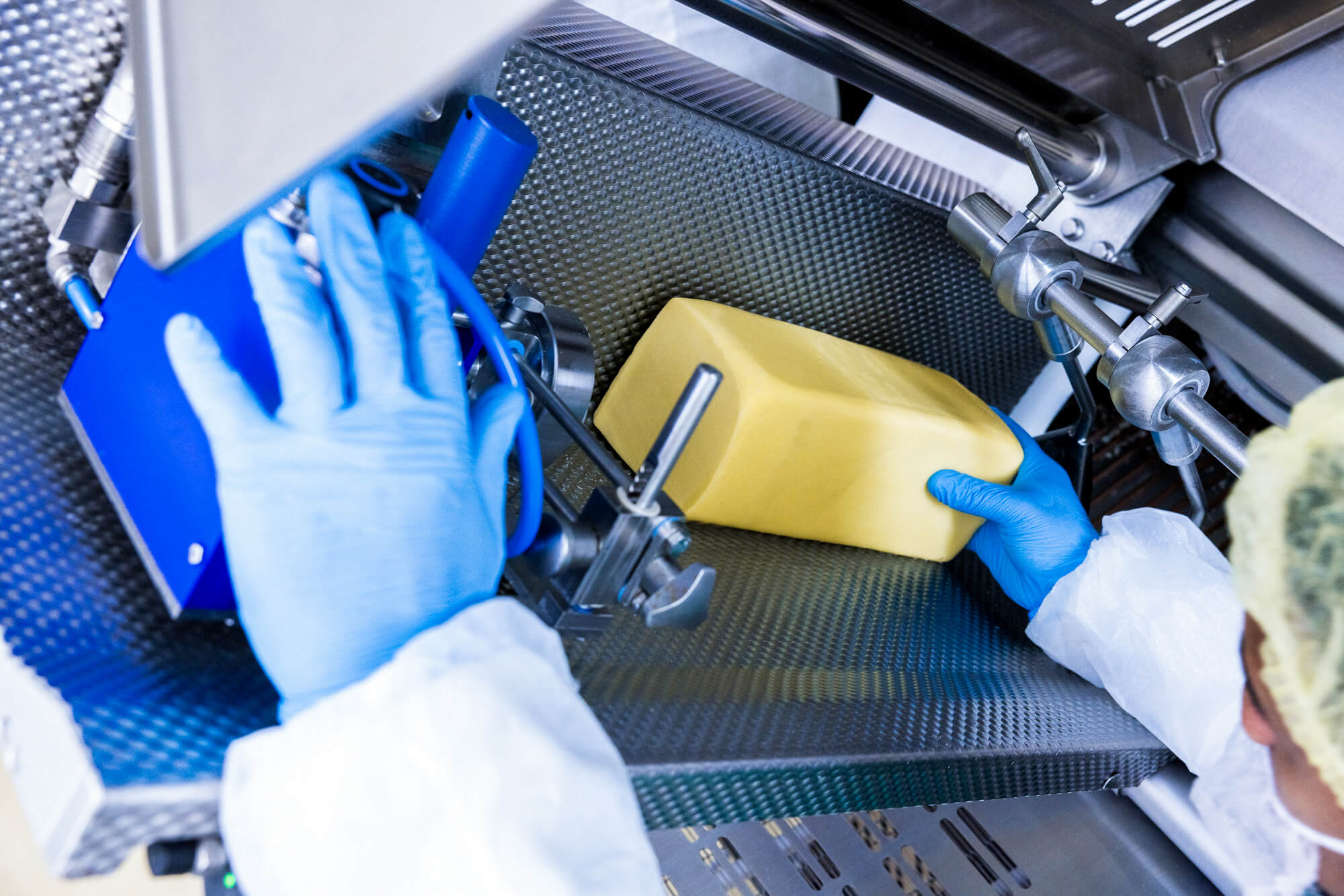

Bizerba offers a comprehensive range of solutions for the food industry with a strong focus on inspection systems, labeling systems, industrial scales and slicers.

Their inspection systems are designed to ensure product quality and safety by detecting and preventing the distribution of defective products. Bizerba's labeling systems provide efficient and compliant labeling for a variety of applications, facilitating traceability and meeting industry standards.

Industrial scales are another key offering, providing accurate and robust weighing solutions to meet the logistical and production needs of the food industry. These scales are essential for the accuracy at various stages of food processing and distribution.

Bizerba's industrial slicers are renowned for their precision and efficiency, providing perfect slicing for a wide range of food products. These slicers are designed to increase productivity while ensuring consistent quality in food presentation.

Their inspection systems are designed to ensure product quality and safety by detecting and preventing the distribution of defective products. Bizerba's labeling systems provide efficient and compliant labeling for a variety of applications, facilitating traceability and meeting industry standards.

Industrial scales are another key offering, providing accurate and robust weighing solutions to meet the logistical and production needs of the food industry. These scales are essential for the accuracy at various stages of food processing and distribution.

Bizerba's industrial slicers are renowned for their precision and efficiency, providing perfect slicing for a wide range of food products. These slicers are designed to increase productivity while ensuring consistent quality in food presentation.

Only one click away

Contact our Food Industry Team now

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again