Quality meets convenience

The processed cheese industry in South Africa has been growing for years. Between 2019 and 2023 alone, sales of processed cheese rose by almost 30%, and market researchers expect annual growth of around 2.6% to over 6% in the coming years. This is serious competition for the medium-sized dairy company Ladismith Cheese. But the passionate natural cheese producers are rising to the challenge and want to offer consumers an attractive, healthier alternative to processed cheese: ready-sliced, long-life natural cheese in attractive, consumer-friendly packaging.

Complex technology from a single source

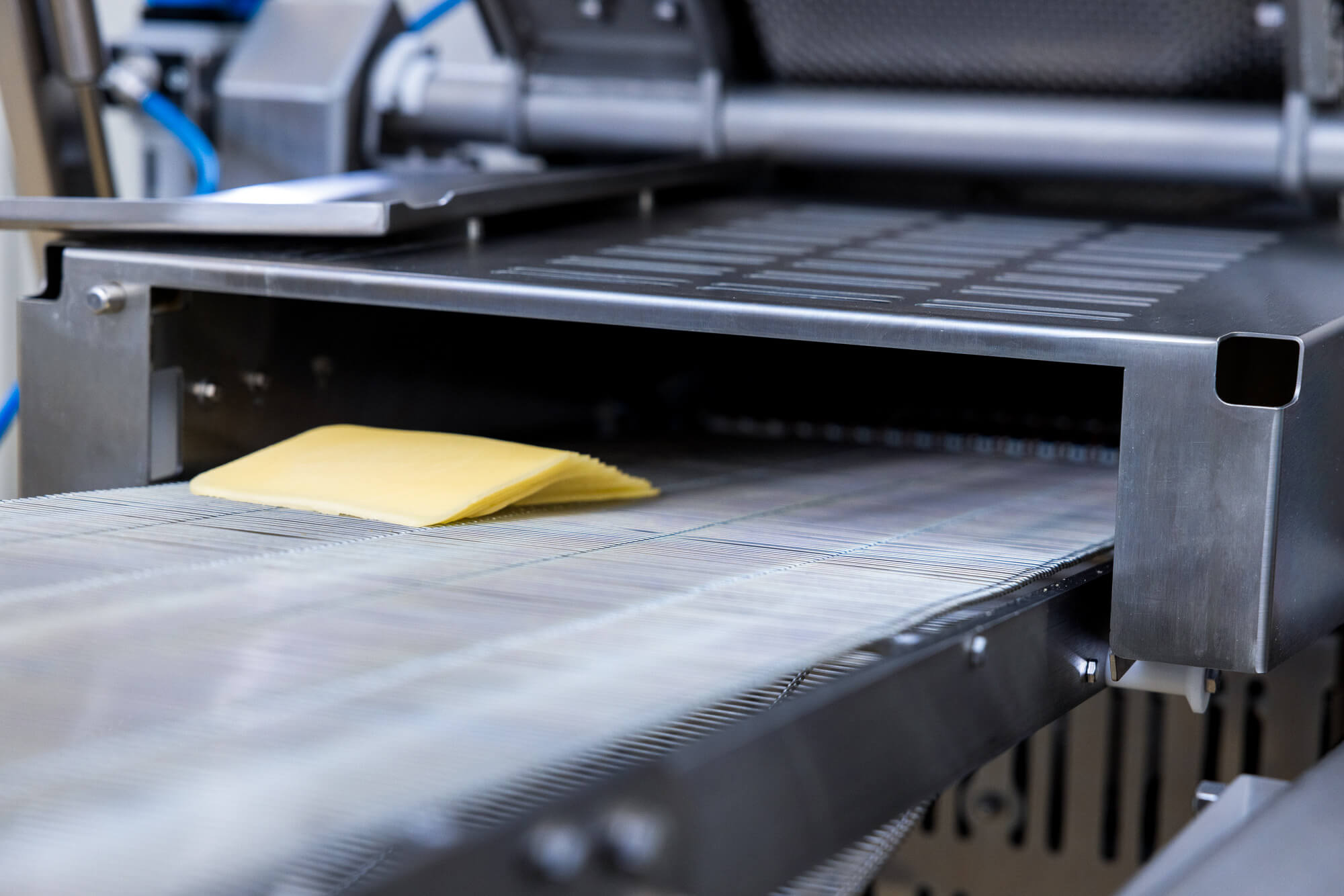

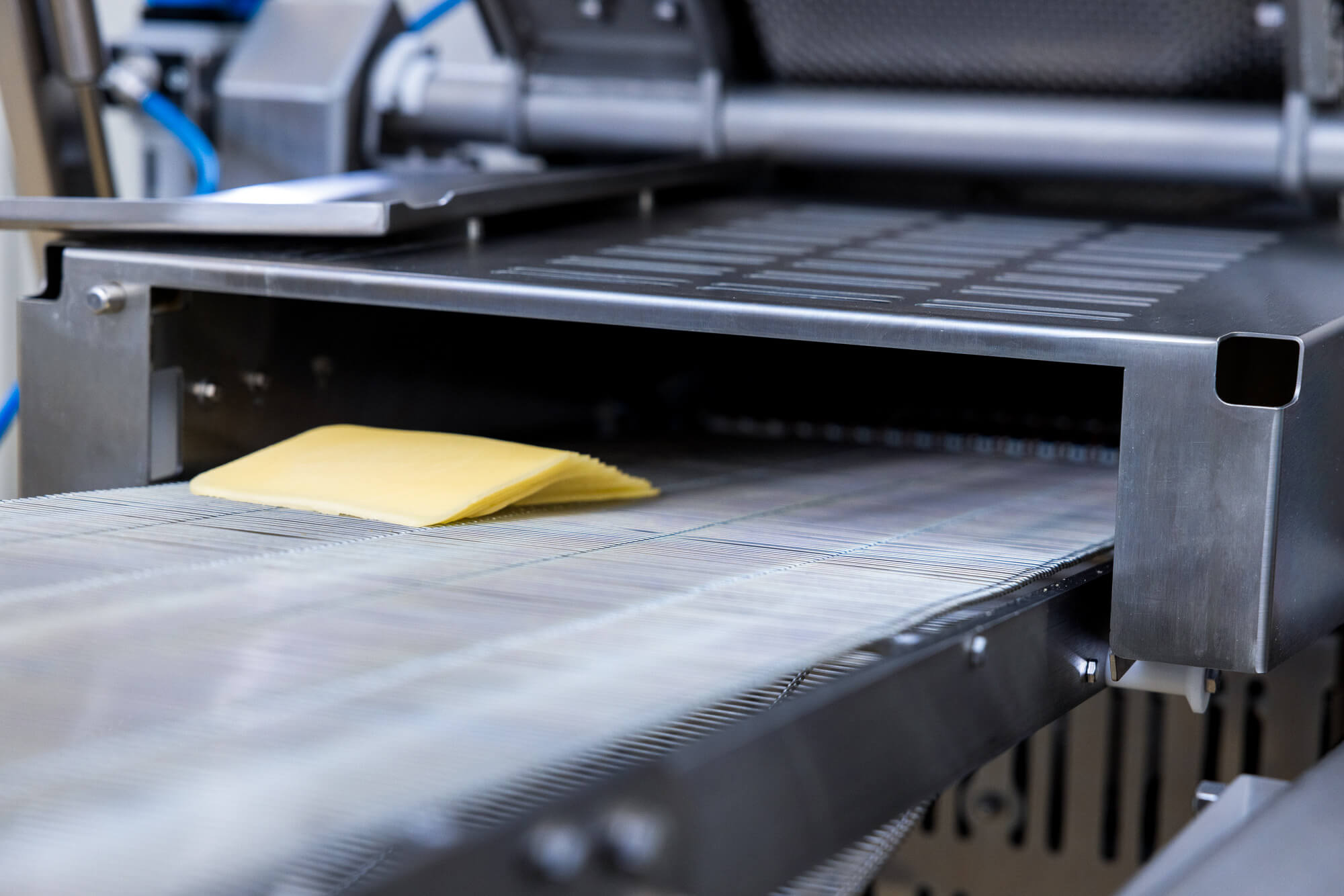

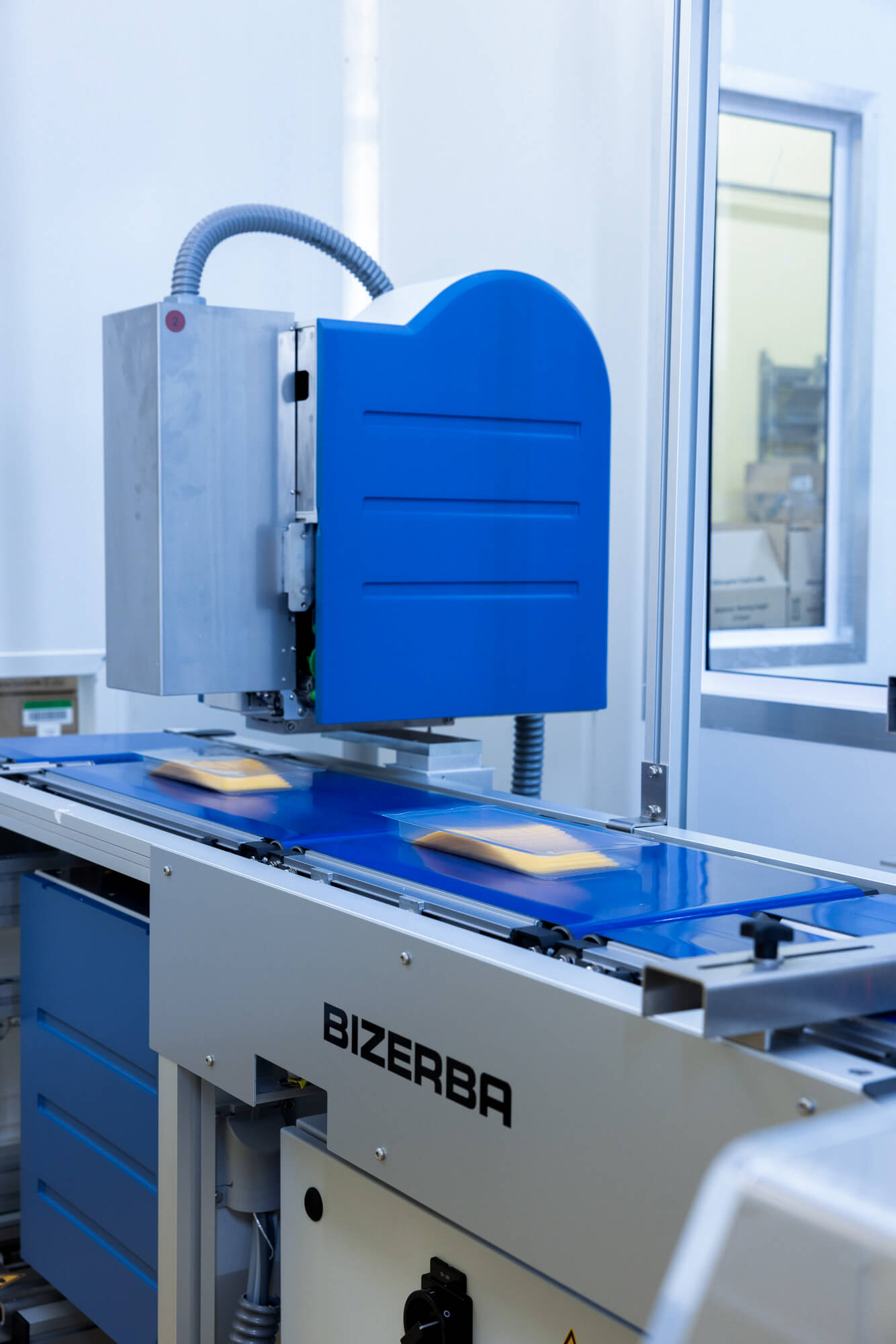

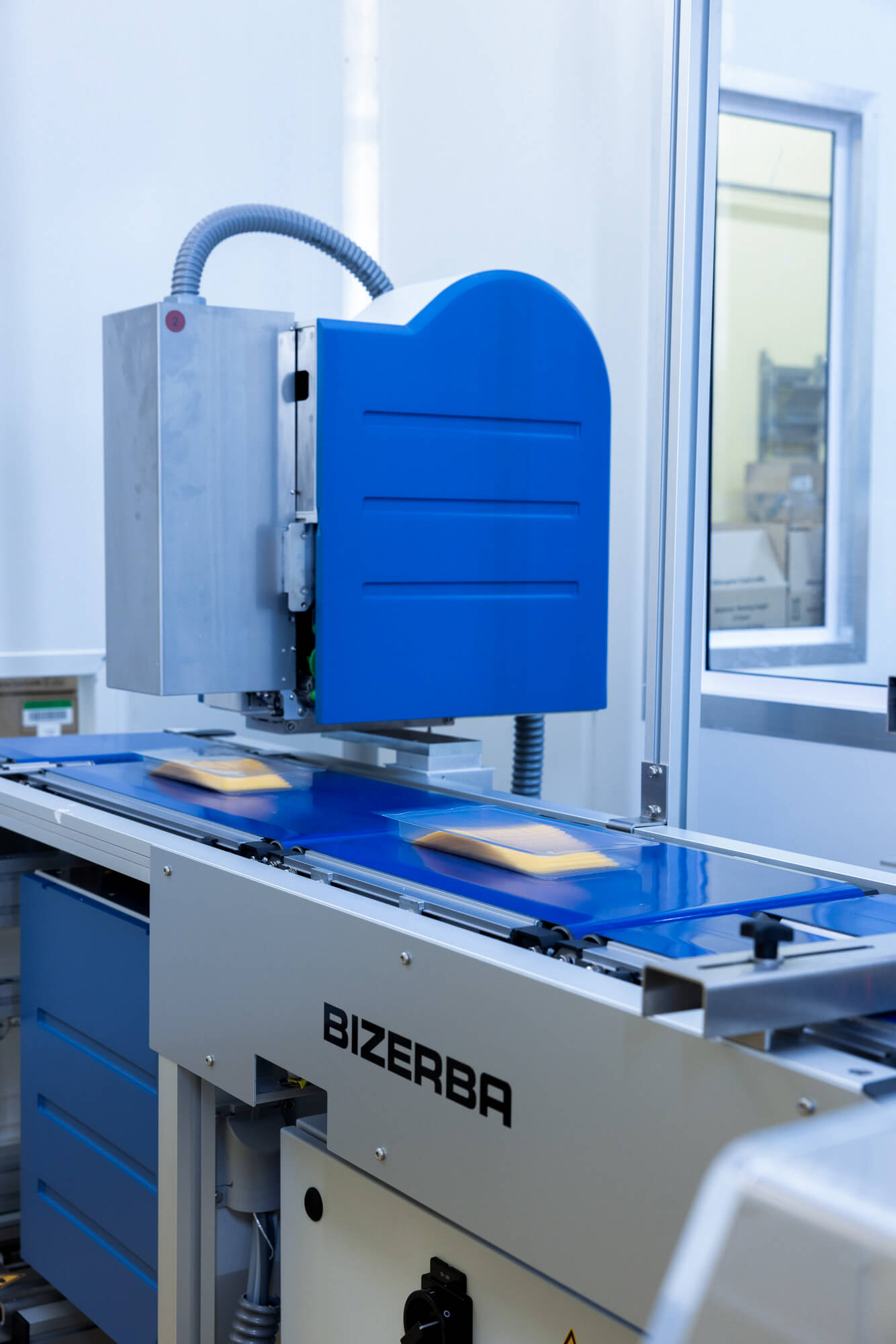

In order to meet the high demands placed on a perfectly made natural sliced cheese, a sophisticated, high-performance production line with various components is required, all of which automatically interlock perfectly - from high-quality slicing to individual labeling. To ensure cost-effective, smooth operation, such a system must also be low-maintenance and easy to service. Everything from a single source: this was ultimately one of the most important decision criteria for Ladismith to commission Bizerba with this project.

- Founded: June 1999

- Headquarters: "Ladismith," South Africa

- Distribution: "Retail," "Wholesale," "Food industry

Increase added value with natural cheese products

Ladismith Cheese was faced with the task of competing not only against established processed cheese producers but also against competitors from its own ranks, as other semi-hard natural sliced cheeses were entering the market at the same time. Products were therefore required that were convincing in terms of quality, packaging and presentation and at least matched the level of the competition. This was the only way Ladismith Cheese could price its natural semi-hard cheese products profitably and increase its added value.

Integration of external components

There were also clear technical requirements: precise cutting to the target weight, MAP packaging in a modified atmosphere, integrated metal detection and precise labeling - all while minimizing waste and yield loss along the production line. The decisive factor was a consistently high level of quality across all product ranges. At the same time, the solution had to come from a single source and all components had to be fully integrated. The remote location of the site made this difficult, as previously only locally available packaging technology could be used. Ladismith Cheese therefore needed a partner who could supply and support a complete line and also reliably integrate third-party components.

Complete solution tops supplement

Ladismith Cheese initially approached Bizerba with the request for a cutting solution that was to be connected to an existing thermoforming machine. During the qualification phase, however, it became clear that a complete solution consisting of Bizerba and Intrama components was the better option for the company - both for budgetary reasons and because of the available space. Successful tests and demonstrations at Intrama and Bizerba confirmed this decision and convinced Ladismith Cheese that nothing stood in the way of installing the new production solution.

Compact dimensions, full performance

Finally, Bizerba implemented an individualized, fully integrated production line with a length of less than ten meters, consisting of the high-performance A560 slicing machine with weighing function, an automatic product loading system from Bizerba and Intrama as well as a thermoformer. A Bizerba line converger aligns the filled packaging on the belt and a metal detector checks for contamination. The final step is labeling with the GLM-Emaxx 50 price and product labeling system with weighing and labeling function. The entire production line is controlled and monitored live by the Bizerba BRAIN2 industrial software.

Hand in hand for the best results

In the course of the implementation, the Bizerba team also successfully made minor adjustments to the Intrama devices. Among other things, a checkweigher was integrated and the thermoforming machine was equipped with a forming and die configuration specially designed for larger packs with higher stacks of slices. Comprehensive training was provided by Intrama and Bizerba to ensure the smooth commissioning of the new line.

Ladismith Cheese has now been working with the new production line for over seven months. The first successes are clearly visible: the natural cheese specialist has expanded its range to include product lines that were previously not available under the Ladismith Cheese brand. Overall, the investment is having a noticeably positive effect on processes, sales and market position. In addition to the direct sales success, the new range of natural sliced cheeses also strengthens Ladismith Cheese's presence - both in retail and in the food service sector.

Alcuni numeri

The Ladismith solution

Il tuo messaggio è in arrivo

Il modulo è stato inviato con successo

Oops! Qualcosa è andato storto

Si è verificato un errore durante l’invio del modulo, si prega di riprovare