Weigh price labeling reimagined: the new GLM-I series in practice

Food producers are facing more complexity than ever. Production lines are expected to grow, with more equipment needed to meet demand, but the physical space—the building—stays the same. That means we have to rethink how we design and integrate equipment to make better use of the available footprint.

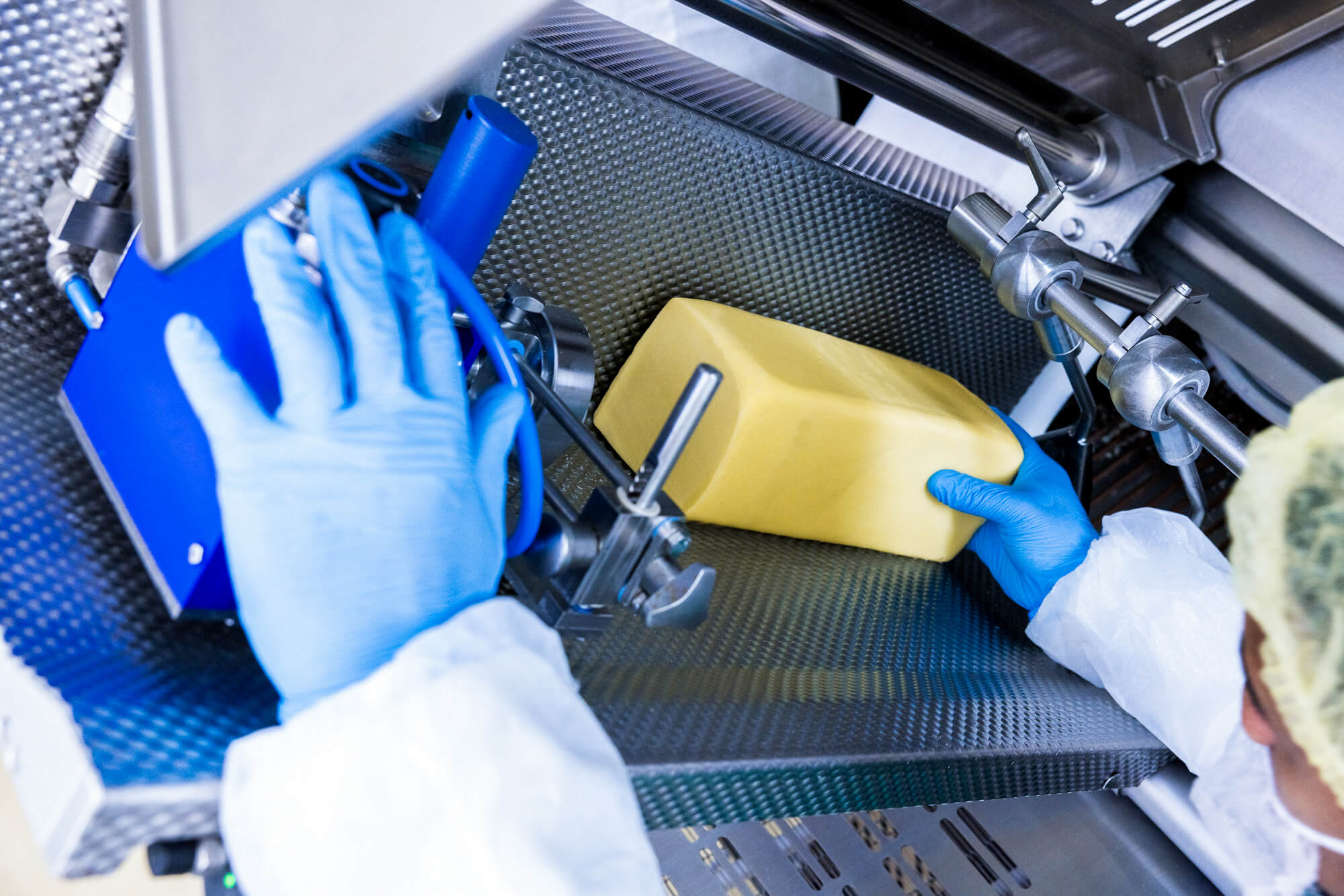

The new GLM-I weigh price labeler is designed with exactly this in mind. It features a modular layout with a variable system length, so it can be adapted to fit the space and transport direction in almost any production environment. It’s compact, flexible and makes full use of the available space.

One of the major upgrades is the accessibility. All labelers can now be operated from the front—no need to turn them off or access them from behind. They automatically move into the right position when a product is called up. Even the bottom labelers reposition themselves. We’ve also increased print speed, which really helps with longer labels and we’ve made label roll changes quicker to reduce setup time and downtime.

Yes, absolutely. The GLM-I is integrated with our BRAIN2 software suite, which allows central management of devices, products and label data. This makes it easier to manage complex production networks with consistent standards and fewer errors.

It’s the ideal solution for food producers who need more flexibility, higher efficiency and better space management in their labeling process. The GLM-I really combines performance and practicality in a very compact format.

Sounds good?

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again