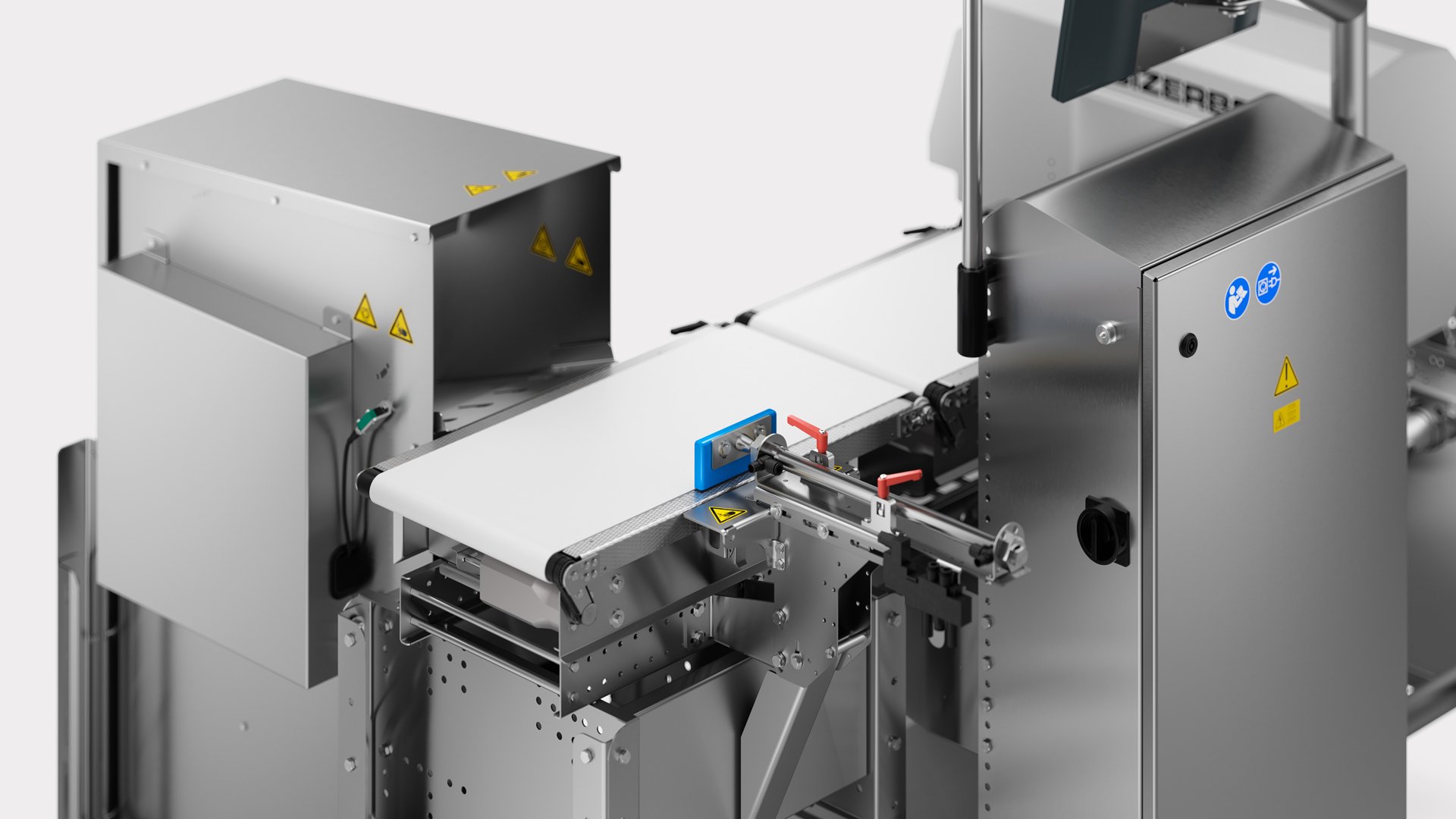

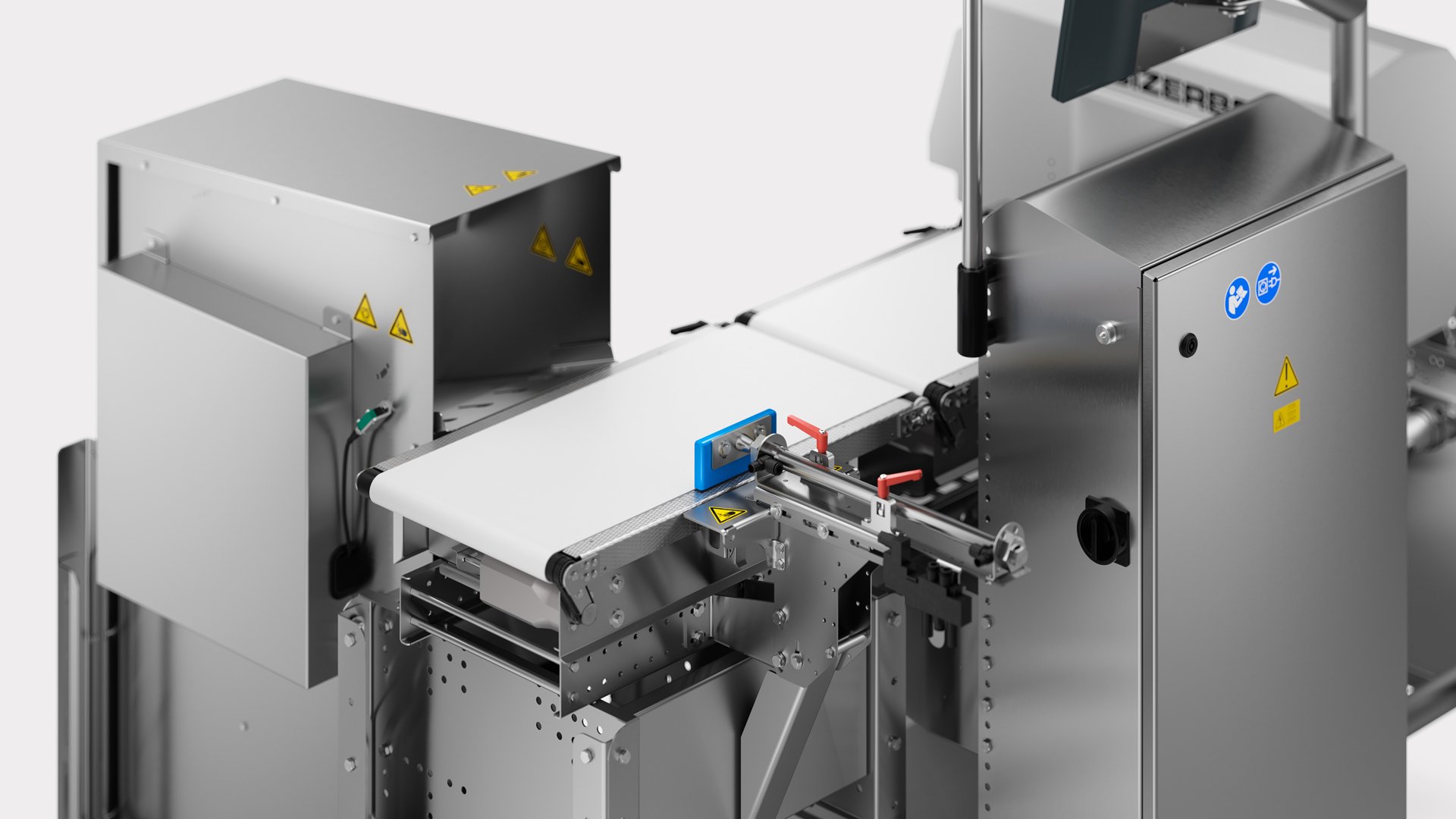

Checkweigher CWE

Robust, reliable and flexible: the CWE is the ideal solution for companies that want to ensure product integrity and legal compliance without compromise. Thanks to its space-saving design, intuitive 16:9 display and expandable electronic structure, it can be flexibly integrated into any existing production line and can be individually configured according to customer requirements. With the CWE, you can control your production process, ensure quality, increase efficiency and thus save time and money. The simple operation, data management and software solutions make your production process transparent. Our unique all-round service is characterized by a coordinated range of services, from integration consulting with individually designed maintenance concepts to project planning for specific requirements.

This checkweigher is particularly suitable for manufacturers of frozen products, ready meals, meat and sausage products, dairy products, non-food products and for legal-for-trade weighing in accordance with pre-packaging regulations.

- Checkweigher

- Fresh Prepared Meals

- Spices, tea, cereals

- Pharmaceutical products

- Confectionery & Ice Cream

- Detection of metal foreign objects

- no spoilage

- Nutrition & Supplements

- Electrical products

- Dynamic weighing

- Dairy Products

- Ingredients, Sauces & Seasonings

- Weight control

- Ingredients & Tobacco

- Pet Food

- Snacks

- Prepackaged products

- Devices & Facilities

- Food Industry

- Metalworking

- Traceability

- Milk & cheese

- Deli

- Detection of foreign objects and product defects

- shape

- Meat & Sausages

- Inspection systems

- Drinks

- Rice, Nuts & Grains

- Analyzing

- Kitchen & Catering

- Packaged products

- Pasta

- Manufacturing & Process Industry

- Fish & Seafood

- Tolerance control

- Statistical control

- Plant engineering

- Breakfast Products & Muesli

- Security

- Convenience Food & Soups

- Fruit & vegetables

- Frozen Food

- completeness

Highlights

Product images and technical information may differ and may not be available in your country.

Areas of use

Details & Options

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again