- located in Istanbul, Turchia

- 50 employees

- 1000 ton of production per year

Adapting to a shifting market landscape

Rising inflation in Turkey has pushed meat prices sharply upward. One effect: consumers increasingly prefer pre-packed sliced meats over traditional deli counter service. For Fümeci, it became clear that a new production setup was needed—one that could deliver precise slicing, high throughput, strict hygiene standards and minimal manual intervention.

Tailored solution required

Erkut Uzun, Project Manager at Bizerba Turkey: “The challenge was to slice 20 different products to target weight, fill them into thermoform packaging and label them—all in a single line. Due to space constraints, we had to design a custom line converger to arrange the filled packs after sealing.”

A trusted partner from the start

A Bizerba customer since 2010, Fümeci once again chose Bizerba as its automation partner—citing not only the quality of the hardware but also outstanding service, digital expertise and deep knowledge of complex line setups.

One decisive factor: Bizerba installed a demo version of the tailored line at Beluga, a Bulgarian partner and supplier of feeding systems. At the on-site trial, Fümeci’s team tested the line with their own products—and left fully convinced. Production Manager Önder Birkan: “The presented solution met all of our expectations.”

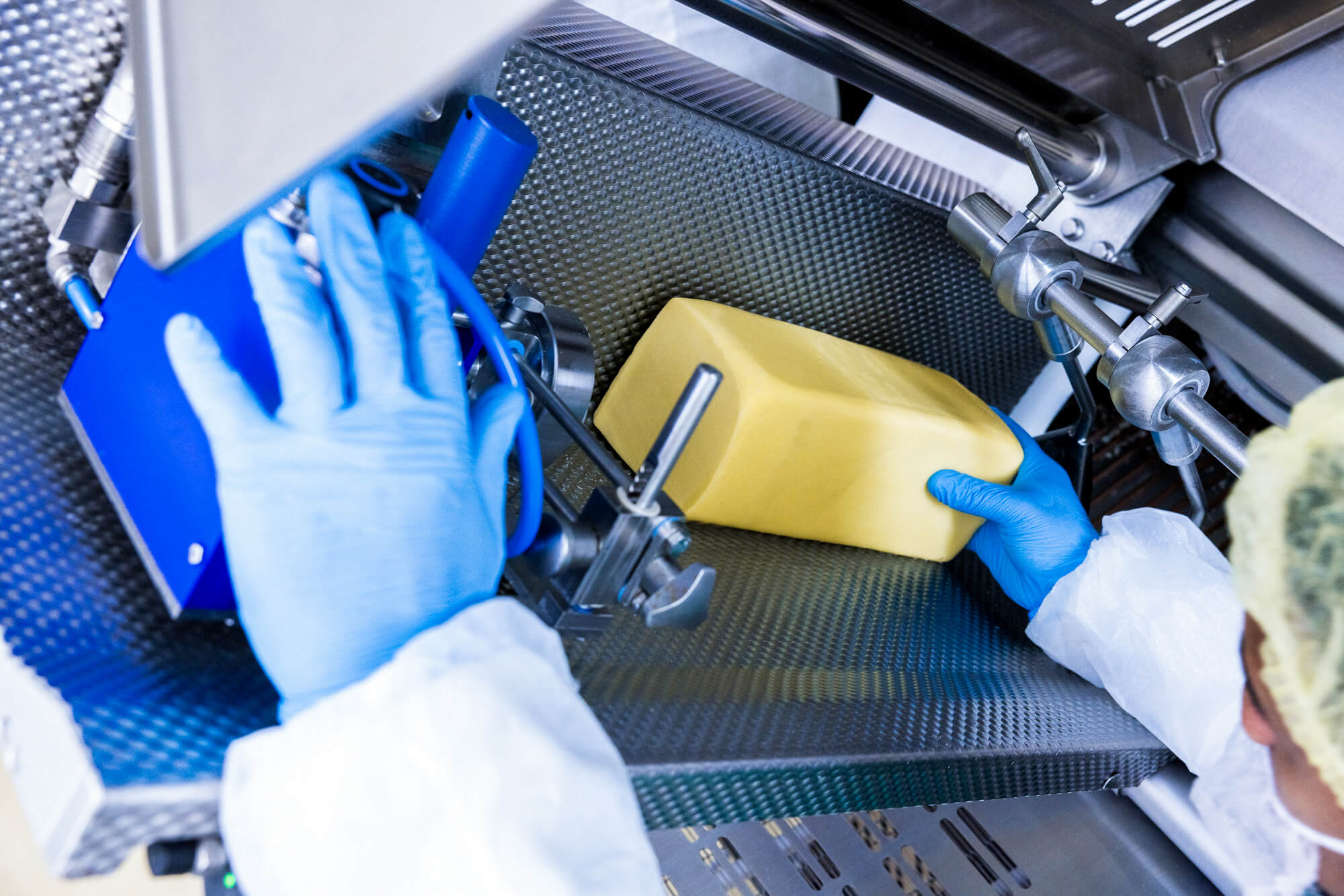

Tailor-made integrated line on just 10 meters

In close coordination with the customer, Bizerba implemented a customized, fully integrated line on just ten meters of production floor—an essential requirement given the limited room available at the production site. The solution includes the high-performance A560 slicer with integrated weighing function, an automatic feeding system from Bizerba and Intrama and a thermoformer. After sealing, a line converger custom-built by Bizerba aligns the filled packs on the conveyor. The final step is labeling, handled by the GLM-Emaxx 50 system, which combines weighing and labeling in one compact unit.

Full transparency with smart software

The entire line is controlled via Bizerba’s BRAIN2 industrial software. Production KPIs are monitored in real time through the BRAIN2 OEE module. Thanks to intuitive user interfaces and in-depth training provided by Bizerba, staff quickly became familiar with the new setup.

Leading the premium segment

“The automation solution has really moved us forward,” says Production Manager Önder Birkan. “We’ve become the leading supplier of premium sliced meats in Turkey.”

Looking ahead: deeper digital integration

Fümeci continues to work with Bizerba as its digitalization partner. The next phase includes integrating additional software tools. For Önder Birkan, one thing is clear:

“Bizerba remains our partner of choice for future automation projects.”

Alcuni numeri

The Fümeci Smokehouse solution

Download

Il tuo messaggio è in arrivo

Il modulo è stato inviato con successo

Oops! Qualcosa è andato storto

Si è verificato un errore durante l’invio del modulo, si prega di riprovare