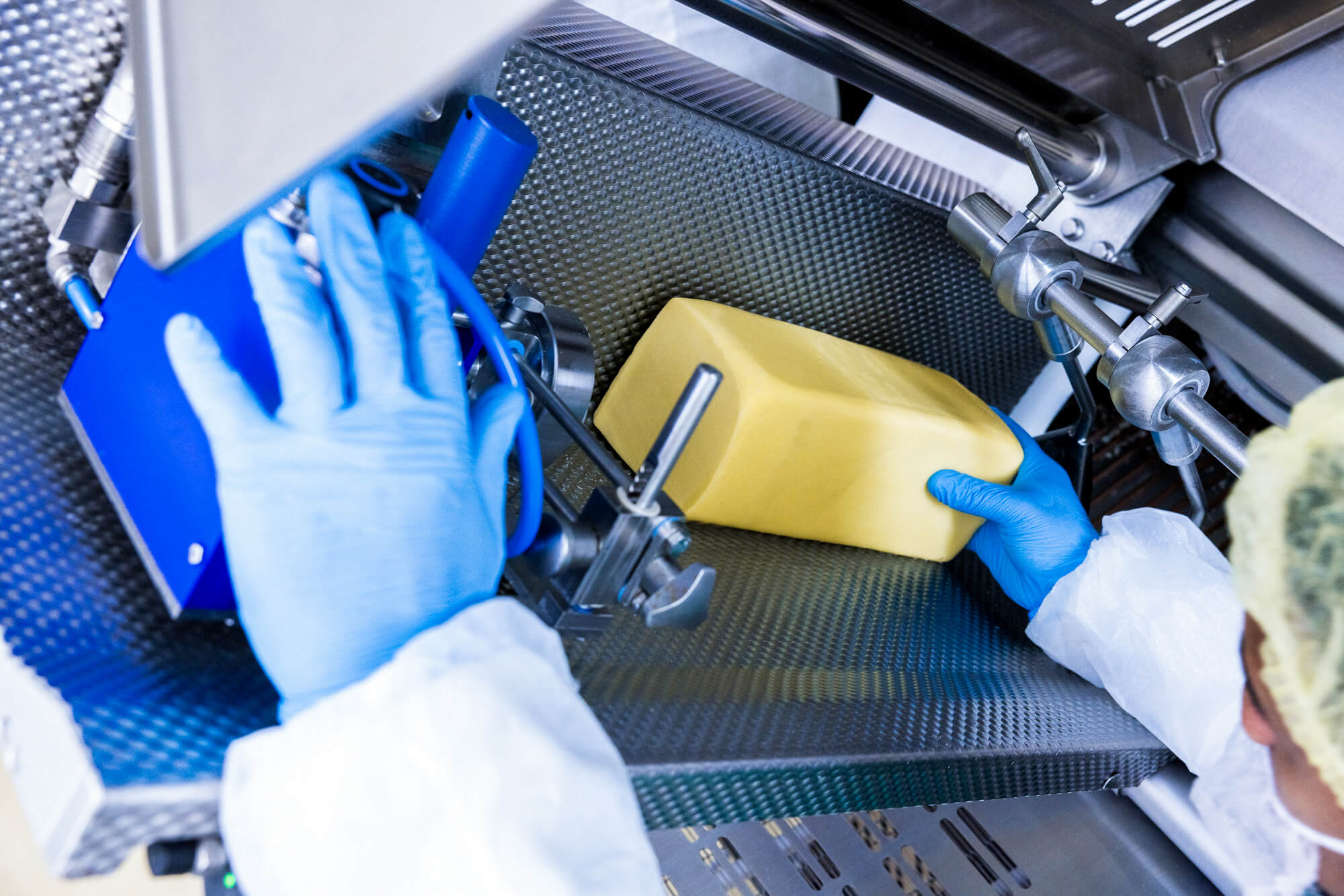

Connected slicers at the fresh food counter: Smarter Slicing for more efficiency

One of the biggest issues is long queues and waiting times. Customers want to be served quickly, but not all machines are used equally or efficiently. That’s where connected slicers and our concept of “Smarter Slicing” come in. It allows us to support operators in their daily tasks while also making all relevant data available to the back office.

With full transparency from the counter to the back office, retailers can analyse how their machines are being used. If some slicers are overused and others underused, it’s easy to adjust the equipment portfolio accordingly. This helps reduce waiting times and queues and ensures the right devices are placed at the right stations.

Indicators support staff by monitoring key tasks like sharpening, cleaning and maintenance. These can be adjusted to fit the specific processes at each counter. You set up one machine with the ideal indicator settings, then create a backup and roll it out across your entire slicer network. This saves time and ensures consistency.

Smarter Slicing helps save resources and ensures maximum slicer availability. At the same time, it supports hygiene by reminding staff when cleaning is due and helps maintain an optimally sharpened blade. It’s really about efficiency on every level—technical, operational and customer-facing.

Sounds good?

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again