When manual inspection processes are no longer sufficient

Many manufacturers have reached the limits of traditional inspection systems. Labeling, allergen management, weight control, and foreign body inspection can no longer be reliably safeguarded manually or visually, especially given changing formats, short product cycles, and demanding packaging requirements.

The effort required for documentation, traceability, and audit preparation often increases more quickly than production lines.

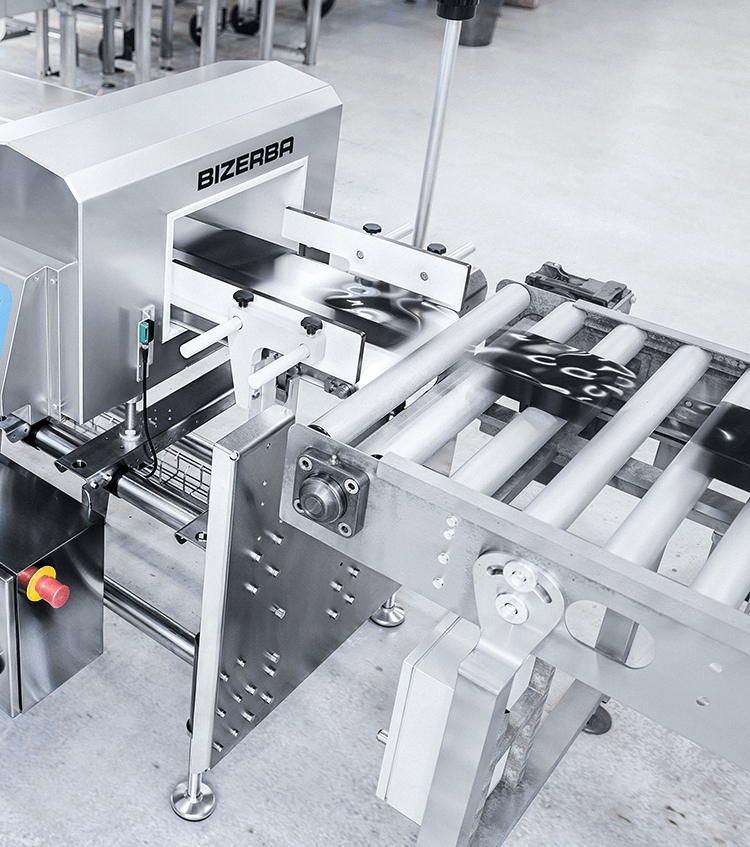

.jpg)