- Year established: 2015 (merger)

- Headquarters: Chicago, IL / Pittsburgh, PA, USA

- Global presence: operating in over 40 countries with 75 factories worldwide

- Product focus: quality food and beverages for consumers and businesses in the foodservice sector

Avoidable costs and downtime

The previous inspection system led to avoidable downtime and increased production costs—ranging from water replenishment expenses to higher unit costs and more downtime. It was clearly time for a change, decided Lee Reece, Global FSQ Technical Excellence Lead at Kraft Heinz.

Focus on new technologies

“The pot can fail in a number of different ways, be that sauce trapped under the seal, the seal overheating or inadequate pressure to form the seal. We needed a system that was going to be capable of picking up all those different faults,” says Lee.

High stakes, clear expectations

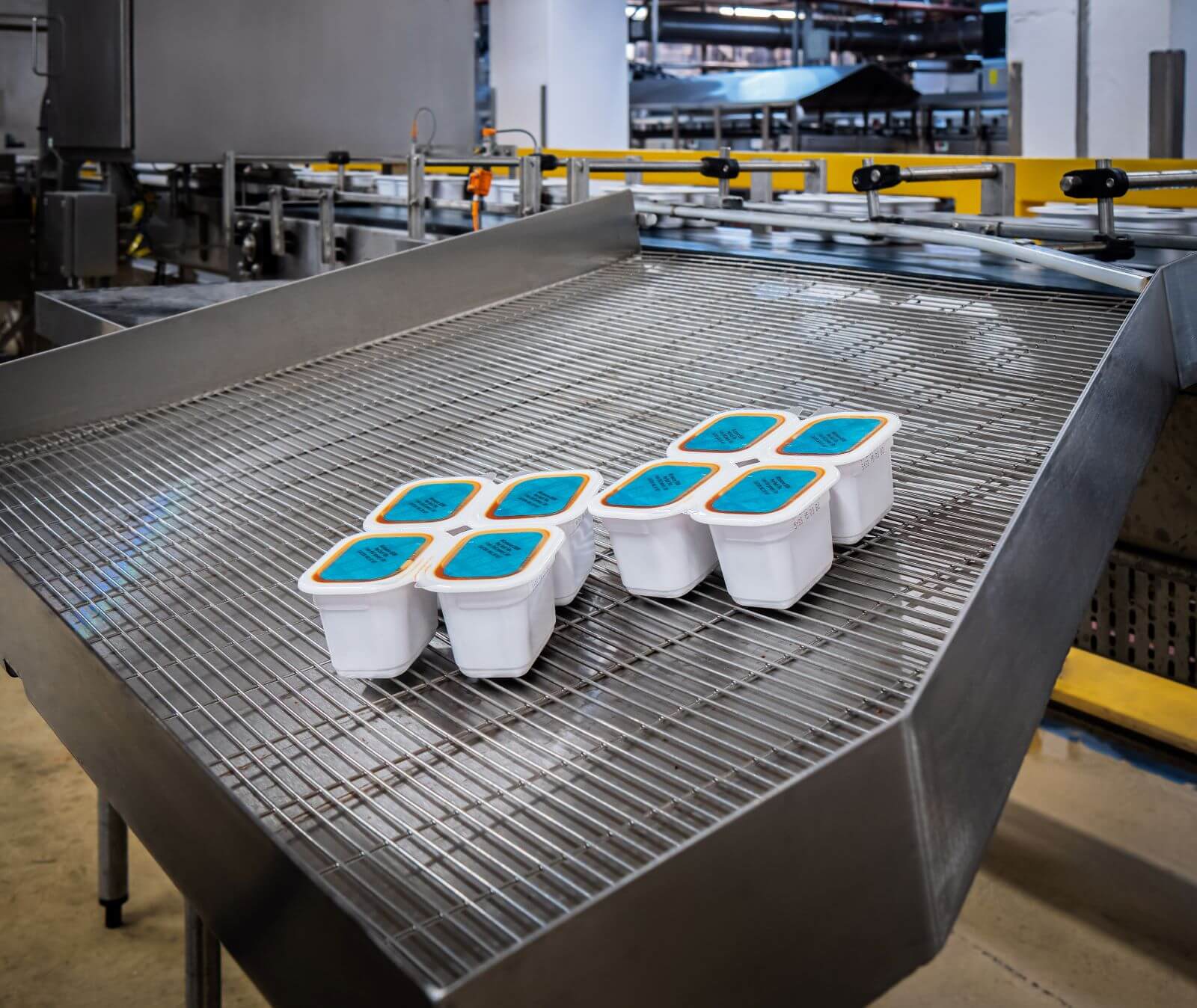

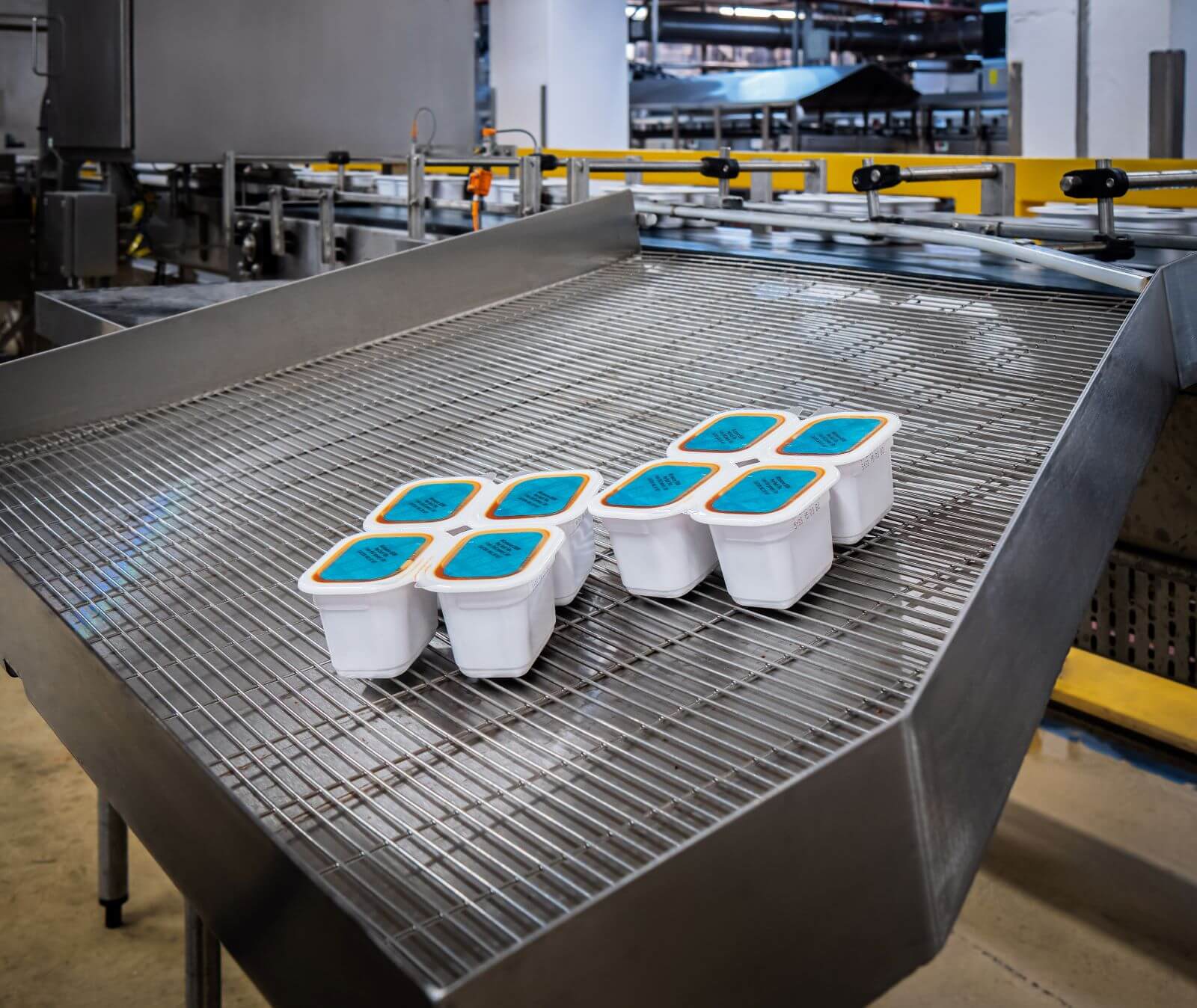

The Kraft Heinz team was looking for a system that would improve overall equipment effectiveness, minimize operational risk and guarantee airtight product sealing. This required detecting even the smallest anomalies—blisters over 2.5 mm, sauce or bean skins in the seal area and breached seals or creased film. The expectations were crystal clear.

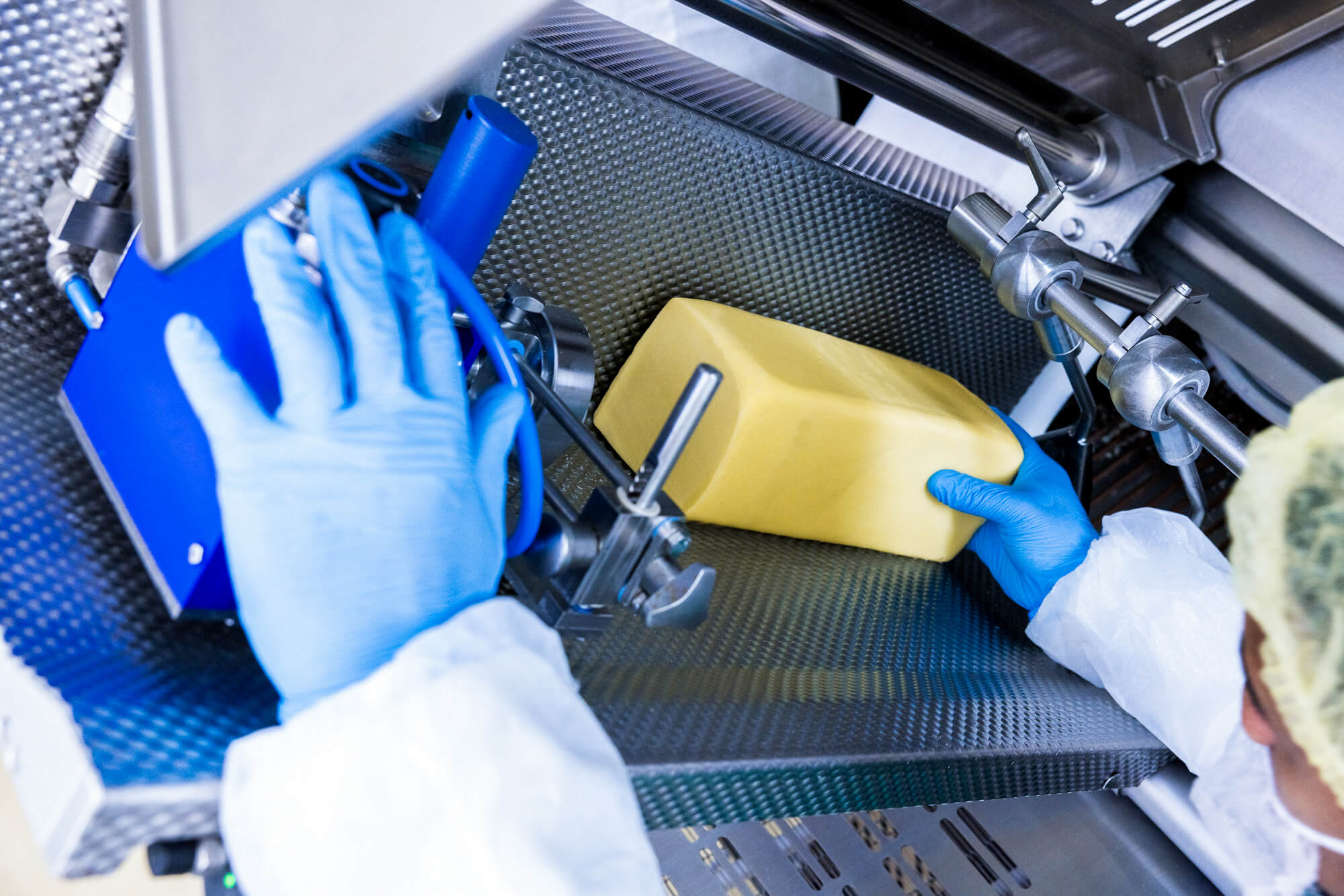

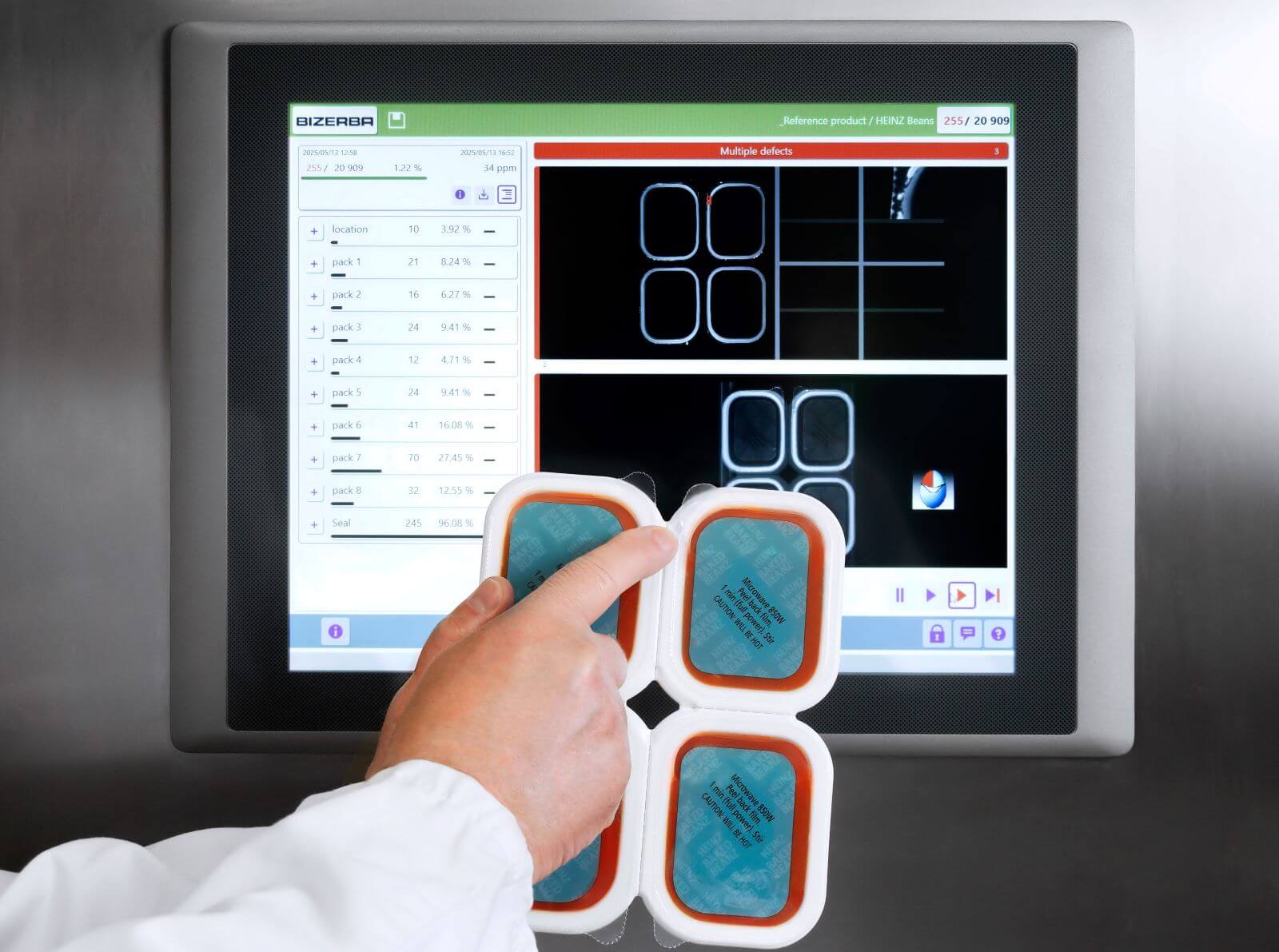

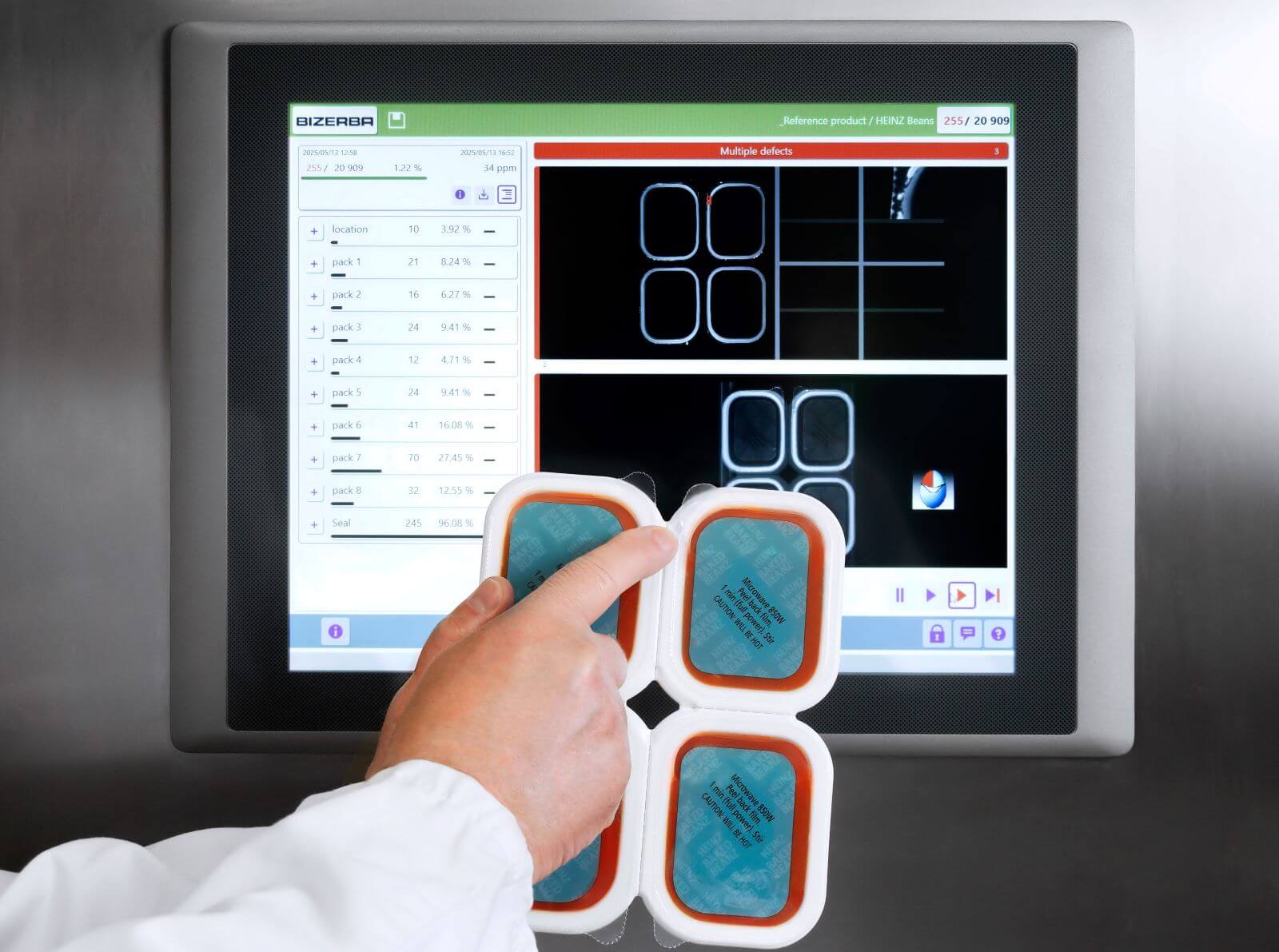

A tailored vision inspection system

Bizerba proposed a fully tailored vision inspection system designed specifically for Kraft Heinz’s needs—without disrupting existing production. The heart of the solution: the SealSecure enhanced by Bizerba’s BRAIN2 industry software and the software module BRAIN2 Capture for seamless documentation and traceability.

Key point — simplicity of the implementation

Bizerba’s project team ensured integration with the existing line, using Kraft Heinz’s current conveyor and reject setup to minimize downtime and reduce costs. “We aimed for zero disruption. That meant adapting our system to Kraft Heinz’s line, not the other way around,” says Adrian Allcroft, Technical Sales Manager – North East, Bizerba UK Ltd.

Seal integrity and efficiency

The new solution meets Kraft Heinz’s exacting sealing standards: no sauce or bean skins in the seal area, no breached seals, no creased film and no blisters of 2.5 mm or larger. Six weeks in, the results speak for themselves: greater confidence in seal integrity, fewer quality issues and a smoother production flow. Operators have praised the system’s ease of use, while the Kraft Heinz team sees long-term potential in its ability to reduce downtime, prevent complaints and protect brand integrity.

The standard of support has been one of the defining factors in the success of the project

“The impact it's had has been significant. We've seen upturns in the efficiency of the line. We've stopped any of the seal faults getting through to further down the process.” says Lee Reece. “The standard of support that we received from the start on this project has been one of the defining factors in the success of the project. It's been a pleasure to work with Bizerba.”

Looking ahead, he adds, Bizerba’s innovative spirit and ability to deliver customized, software-integrated solutions make them a valuable long-term technology partner. “It's been a partnership and it's growing every day,” confirms Adrian Allcroft.

Let’s count

The Kraft Heinz Wigan solution

Downloads

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again